BERKELEY COACHWORKS

The engineering team at Berkeley Coachworks has evolved a design for a new chassis which will be used for a variety of vehicles in the Berkeley line-up.

To highlight the company’s capabilities and the flexibility of the chassis design, Berkeley Coachworks has already developed a number of designs developing the essential Berkeley DNA into a fresh styling direction for a new era of small, lightweight sportscars.

These will include mid-engine ICE configurations for i4, V6 and V8 powertrains, as well as EV and Hydrogen powered cars. We are also developing a front wheel drive 3 and 4 wheel electric 'skateboard' chassis for future models.

In the old tradition of coachbuilders, we can take your styling idea and transform it into reality. Using the latest CAD design software, early sketches can be efficiently turned into fully considered designs for the extra special touch of individuality.

Our bespoke services for exterior and interiors styling along with your choice off powertrain can make your Berkeley a unique and compelling companion.

INNOVATION

The Berkeley brand has always innovated. Having been one of the first to use a composite chassis, we are keen to follow the tradition but add a new twist.

Looking for a fresh approach, our team explored the use of plant based materials in the construction of the new composite chassis, eventually specifying a blend of flax to replace carbon fibre and tree resins to replace the chemical resins. This is now known internally as our ‘Bio-chassis’.

The Bio-chassis forms the basis of the new Berkeley car range combining a lightweight monolithic structure with modern running gear, advanced double wishbone suspension and push rod actuated spring damper units.

Future testing of the bio-chassis and its technology will be carried out using a combination of virtual computer FEA analysis and real world track testing.

The track testing schedule also gives us the ideal testing ground for the electric motors and batteries for the Berkeley Bandit GT electric car due to be launched in 2023/4.

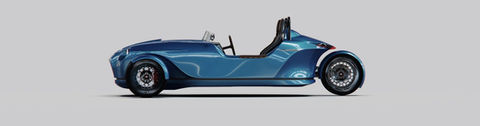

BERKELEY SE328

The original Berkeley SE328 was manufactured between 1957 and 1958 using a 328cc two-cylinder engine producing 18bhp driving the front wheels. 1259 cars were built, with many exported around the world.

Our work on the new Berkeley initially concentrated on a modern version of the SE328, featuring a two-stroke engine powering the front wheels.

With the design work and technical specification set, the car scored well in consumer feedback clinics. There are plans to produce a highly limited edition run of the new SE328 as many of its components are shared with our new Berkeley Bandit models.

Our Berkeley SE328 concept model features a 2-stroke engine. Using the latest direct injection technology, the 2-cylinder engine produces 164bhp in a unit weighing only 42kg and is coupled to a CVT transmission driving the front wheels.

BERKELEY

SUPER 60

Berkeley's original three-wheeler model was introduced in September 1959 and was an instant success in the UK where three-wheelers could legally be driven on a motorcycle licence, so were suitable for a motorcyclist with family.

They were fitted with the 328 cc Excelsior Talisman engine like the older SE328, and the four speed and reverse type VR gearbox, and were available as both soft and hardtops.

The chassis plate, mounted on the bulkhead above the brake master cylinder, was the printed SE328 type but with 'T60' stamped in the chassis number block along with the chassis number. Chassis numbers run from 1 to approximately 1800.

The first 600 cars (approximately) had a bench seat with an umbrella-type pull handbrake and aluminium reinforcement sections in the punt body section. Cars thereafter had steel punt chassis sections, bucket seats and a floor-mounted handbrake lever.

In their road test of October 1959, The Motor Cycle magazine described the car as "a fascinating, front-wheel-drive sports car which combines economy with liveliness and superb cornering."

.png)